Delcam CRISPIN Launches 2010 CADCAM Range for Footwear

Share:

Delcam CRISPIN has released the 2010 versions of its range of design and manufacturing software for the footwear industry. The new versions include significant enhancements to the LastMaker and ShoeDesign programs, plus general speed and ease of use improvements across the full range. Delcam CRISPIN is the world's largest supplier of CADCAM software to the footwear industry and is the only supplier able to provide a complete solution for the design and manufacture of lasts, uppers and soles.

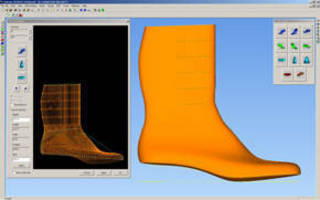

The main addition to the 2010 version of the LastMaker program is the ability to design a boot leg extension for an existing last. Control planes to modify the shape of the boot may be created up the leg of the last, positioned either by specific measurements or by percentages of the last length. Once the design has been finalised, it is possible to grade the leg height, together with the other areas of the last, and to generate the required machining instructions.

Improvements to the heel height functionality allow the height to be increased or decreased without affecting other parts of the design. If desired, this option can maintain the bottom length measurement of the last.

LastMaker has also been made more capable in the creation of orthopaedic footwear. A common condition with this type of footwear requires the last design to be curved to match the curvature of the patient's foot. To accommodate this problem, new functionality has been added which can modify the shape from the bottom mid-section forwards, allowing the last to be bent either inwards or outwards.

The ability has also been included to add an insole block to the bottom of the last, increasing the overall depth of the last for patient's with different leg lengths. The block can also be edited to include a rocker in and around the ball area to aid the walking process. It is also possible to produce an orthotic shape, using the bottom surface of the last as the template for the orthotic.

The 2010 version of ShoeDesign has seen big changes to the user interface. A number of new icons have been added to give easier access to commonly-used commands. However, the icons are divided across a smaller number of menus, with only the required icons displayed for the process and functionality being used. This provides a clearer and more intuitive user interface.

A new shape editor has been added, along with a new section within the library of parts to manage the shapes. Shapes can be created or edited either in ShoeDesign or in the Engineer Pro software for 2D pattern development, and then used in both programs. To speed up the design process, the ability has been added to copy and paste all the parameters, including material thickness, texture and colour, from one panel within the upper design to another with a single command.

Improvements to the snapping functionality have been made, especially when creating lines that intersect with, or are positioned near to, the feather edge, making point editing and panel definition much easier. These changes have also made it easier to create and modify very narrow panels.

For the 2010 release, Engineer Pro includes two modules as standard that were previously cost options, TechPac and StitchTec. TechPac is a 2D solution for producing technical packages, including technical information, images and manufacturing operation sequences. Reports can be generated in PDF and HTML formats for factory operatives to follow, which give them all the technical information required for the upper assembly processes like clicking, skiving, folding and closing. TechPac also includes new functionality to calculate the visible net material areas of shoe.

The StitchTec module enables the 2D engineering of the pallets and stitch paths for upper part components that are stitched together using automatic stitching machines