Ultrasonic Welding Plays Increasingly Key Role in Photovoltaic Cell Manufacturing

Sonobond Ultrasonics' Foil Splicer(TM) Used by Leading Photovoltaic Manufacturers Throughout the World

WEST CHESTER, Pennsylvania, April 3, 2007 - With concerns about global warming and rising energy prices driving more businesses and consumers to consider alternative forms of energy, Sonobond Ultrasonics' MS5010B Ultrasonic Foil Splicer(TM) has seen increased interest from some of the world's leading solar panel manufacturers.

"The Foil Splicer(TM) welds the aluminum interconnects between the photovoltaic cells to boost voltage and current," explains Janet Devine, president, Sonobond Ultrasonics. "The equipment delivers mechanical vibratory energy under pressure to create ultra-reliable, solid-state mechanical bonds."

Benefits of Ultrasonic Bonding

Ultrasonic bonding has a number of benefits over other methods of bonding. The bonds created by the Foil Splicer(TM) have essentially the same strength and structure as their parent materials. There's no melting and no need for excessive heat, fluxes, filler metals, tapes, or other consumables. The higher frequency operation of the Foil Splicer(TM) avoids cracking of the glass panels in the photovoltaic cells. Additionally, the Foil Splicer(TM) is faster than other splicing methods, does not distort materials, and requires minimal operating and training costs.

Foil Mill Applications

The benefits of ultrasonic bonding that have led the world's leading photovoltaic manufacturers to use Sonobond's Foil Splicer(TM) have also made it an integral part of utility aluminum and copper foil mill operations across the globe. The Foil Splicer(TM) provides the fastest and cleanest way to join aluminum foils, making nearly every other method of splicing obsolete. It easily achieves consistent, flawless splices in foils as thin as 0.00017" and up to 0.006" thick and 72" wide. The fine ultrasonic seam welds that have metallurgical and dimensional characteristics similar to the original metal foil, help facilitate additional processing, such as re-rolling, laminating, and printing.

Foil Splicer(TM) Specifications

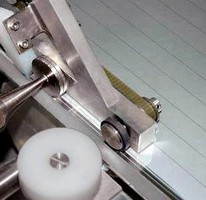

The MS5010B Foil Splicer(TM) consists of a power unit with a solid-state frequency converter, a welding head, and a rotating disk tip that traverses the width of foil at speeds up to 15 feet per minute depending on thickness and type of alloy. It can be easily fitted to most foil mill separating and splicing machinery.

A Leader in Ultrasonic Welding Technology

Sonobond is a worldwide leader in the application of ultrasonic welding and bonding technology. In 1960, Sonobond, then known as Aeroprojects, received the first patent ever awarded for ultrasonic metal welding. During the intervening 47 years, Sonobond has earned an outstanding reputation for its pioneering work and quality-engineered products. Today, Sonobond manufactures a complete line of welding and bonding equipment for a wide variety of customers in the automotive, appliance, electrical, HVAC, aerospace, filtration, medical, and apparel industries.

More information on Sonobond's ultrasonic welding technology, plus specific information on Sonobond welding equipment, is available by going to its website, SonobondUltrasonic.com, or by calling 800-323-1269.

1191 McDermott Drive, West Chester, PA 19380

Phone: 610-696-4710 Fax: 610-692-0674

Internet: SonobondUltrasonic.com

Email: info@SonobondUltrasonic.com

Contact: Janet Devine

610-696-4710