Siemens to Demonstrate KUKA Robotics Integration

All motion controlled by mxAutomation directly through the Sinumerik CNC -

simple to integrate, even easier to operate

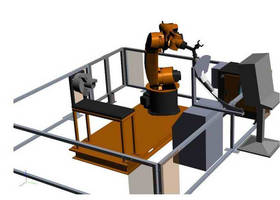

CHICAGO - At this year's International Manufacturing Technology Show (IMTS) in Chicago, Siemens will demonstrate its recent collaboration with KUKA Robotics. In the Siemens booth E-5010, a KUKA robot will be articulating parts, simulating the operation on a CNC machine tool. Key to this development is the machine builder's ability to integrate mxAutomation from KUKA directly through the Siemens Sinumerik CNC platform, thereby allowing the operator of the machine to run both the machine tool and robot from the single control panel.

The motion sequence of the robot is entirely engineered within the Sinumerik 840D sl CNC, then transferred by the 840D sl's PLC function to the mxAutomation interpreter on the KR C4. All program changes to a six-axis robot can easily be input on a second channel of the CNC and fully operated. This scenario provides the ability to not only run a machine tool's automation sequence more efficiently, but also make more changes on-the-fly to minimize machine downtime, with no special knowledge of robot programming language. During the operation of the machine tool, all changes made can be visualized directly on the CNC screen, further minimizing operator actions.

Siemens is the first CNC supplier to show this capability for single-screen operation of the machine tool and robotic materials handling on the CNC.

During the show, a Siemens Sinumerik 840D sl CNC will be programmed to allow the operator to jog the robot, command the gripper and otherwise simulate integrated actions with a machine tool.

In operation, the KRC4 integrator and mxAutomation convert the robot language into the same commands used for multi-axis machine tool functions. A single Profinet cable runs between the robot and the CNC. According to KUKA's Andreas Schuhbauer, key technology manager for machine tool automation (Augsburg, Germany), "mxAutomation allows the machine tool builder a single I/O language for integrating robotics on the CNC, while the end user operator can run both the machine tool and the robot from a single screen on the control."

mxAutomation for Sinumerik CNC was a joint development between KUKA and Siemens. KUKA created plug-in function modules for the Siemens Step 7 PLC engineering software and provided its robot knowledge to Siemens for creation of the second channel logic on the CNC, Andreas Schuhbauer further noted.

All safety functions and test functions for load / unload, brake test, gripper, robot communication and safe operation of the robot are provided through the Siemens Profinet and Profisafe platforms.

Future developments for mxAutomation are planned, including a wider application range for robots in the CNC machine tool environment.

Mr. Schuhbauer from Kuka will be in the Siemens booth at IMTS for interviews on this topic.

For more information about Siemens CNC solutions for the machine tool industry, visit our website: www.usa.siemens.com/cnc. Join the user community by following us on Facebook: www.facebook.com/SiemensCNC and talking to us on Twitter: www.twitter.com/siemens_cnc_us.

Please forward all inquiries to:

Siemens Industry, Inc.

Motion Control Business

390 Kent Avenue

Elk Grove Village, IL 60007

Attn: Marketing Communications

For specific product information and inquiries, call (800) 879-8079 ext. Marketing Communications or send an e-mail to: SiemensMTBUMarCom.industry@siemens.com

CONTACT:

John Meyer

(847) 640-1595

john.meyer@siemens.com