Roxtec Sealing Solutions Offer Superior Protection in Food Manufacturing OEM Applications

Food manufacturing facilities are consistently exposed to cold air temperatures, hot water, chemicals such as chlorine and large amounts of high-pressure hosing during required daily wash downs. While these practices create a high risk for corrosion and damage to machinery, proper sealing and protection of electrical components enables facility equipment to withstand harsh conditions. With the right protection, long-term operational reliability of machinery is increased, and Overall Equipment Effectiveness (OEE) is improved by minimizing unplanned downtime.

Roxtec cable entry seals meet IP 66/67 and UL/NEMA 4, 4x, 12 13 standards, and increases mechanical reliability for a wide range of robotics and machinery in the food manufacturing industry, including Filling and Closing, Labeling and Coding, Form-Fill-Seal, Wrapping and Palletizing machinery. Roxtec seals are also ideal for control panels, power distribution panels, Human Machine Interface (HMI), motor control centers, junction boxes, and cable management.

Roxtec sealing solutions offer superior protection and a number of cost reducing benefits for a wide range of food processing and packaging OEM applications. Roxtec seals provide airtight and watertight protection that prevents water from entering and damaging equipment during high pressure hosing, allowing for easier machine cleaning and increased hygiene. Roxtec seals also protect electrical equipment from dust, debris and chemicals that can cause cable failure and lead to unnecessary machine downtime.

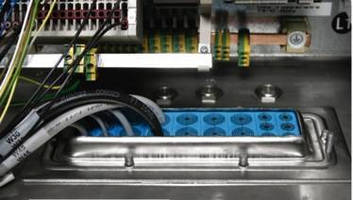

Roxtec sealing systems consist of rubber sealing modules, compressed within a corrosion-resistant stainless steel frame option that can be used in wash down applications. The rubber modules within the frame are designed with the Roxtec technology, Multidiameter™. This technology is based on modules with removable layers that enable sealing of single or multiple cables and pipes of different sizes. Roxtec's innovative design drastically simplifies installation and maintenance and significantly reduces costs when compared with stainless steel (SS) glands.

The superior protection offered by Roxtec sealing solution leads to reduced long-term cost and increased operational reliability, which are huge advantages for food manufacturers and packaging OEM applications.

To learn more about Roxtec, visit: www.Roxtec.com