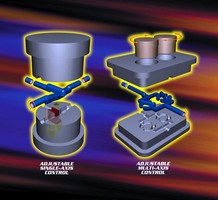

New Imarc(TM) In-Mold Rheological Control Technology from BTI Gives Processors Adjustable Single Axis or Multi-Axis Control of Melt Flow

Processors Can Adjust Flow Patterns TO and WITHIN Cavities, Without Changing Gate

Locations, Part Geometry or Process Conditions

ERIE, PA (July 11, 2006) - Today's traditional injection molding know-how limits processors to one dimensional linear control of the melt after the polymer leaves the injection nozzle. Understanding that there are non-uniform three dimensional viscosity changes that occur to the melt as it flows through the mold, Beaumont Technologies, Inc. (BTI) introduces new iMARC(TM) in-mold adjustable rheological

control systems technologies to enable processors to better control and take advantage of rheological changes...all without ever having to take the mold out of the press. It can be best described as a 3 dimensional molding technology.

This latest advancement in melt-management, which is based around the firm's popular MeltFlipper® and MAX(TM) technologies, is a major step forward for the injection molding industry. The rheological control system will be offered to customers in a variety of standard insert sizes and melt-management designs. Custom designs will also be offered for unique applications.

The basic premise of iMARC single axis or multi-axis molding technologies is to allow processors not only to dynamically optimize mold balance from cavity to cavity, but also dynamically change and control the actual filling pattern within a given cavity...all without changing gate locations, part geometries, process conditions, or having to take the mold out of the press. Much like standard MeltFlipper technology, these latest advancements are applicable in all cavity ranges and all molding materials, including single cavity molds and LCP materials.

The new iMARC technology can, among other things, provide an unprecedented level of control within the mold and cavities to:

o provide a universal mold balance,

o reduce scrap rates,

o reduce mold startup and qualification times,

o provide a much wider process window,

o create stronger weld lines (to eliminate part breakage issues) or move weld lines to non-cosmetic areas,

o eliminate filling problems in areas such as thin wall sections,

o eliminate short shot issues and gas trap locations, and

o solve cosmetic problems, including "glass-migration" by manipulating the arrangement of glass fibers in the polymer.

As a result of using rheological control technologies, users can optimize each mold for the particular product being produced and account for viscosity variations created naturally by different machine nozzles, material lot changes and sprue bushings...thus creating a more universally adaptable mold from machine to machine.

Ongoing molding demonstrations were conducted at the BTI booth during the NPE show to highlight the rheological control technology. It was also demonstrated/proven on a 1944 Van Dorn hand operated injection molding machine. The purpose of doing this was to readily prove to processors that any type of injection molding machine - old or new - can produce higher quality parts more efficiently by controlling the rheology of the melt within the mold.

Beaumont Technologies, Inc., headquartered in Erie, PA, offers a unique mix of products designed to optimize the efficiencies of the mold, parts, and the injection molding process. These products and services are tools that help the injection molding industry become more competitive and profitable in world markets. The company's expertise lies within an in-depth understanding of polymer flow and processing technologies which enable molders and moldmakers to decrease lead-times while maintaining a high quality level of process and part control. Products include the patented MeltFlipper® melt rotation technology guaranteed to balance filling in hot and cold runner applications, the 5 Step Process(TM) mold commissioning software, CAE by BTI(TM) flow analysis services, and BTI Training Seminars.

For more information on the new iMARC technology product line, contact:

Technical Sales Department, Beaumont Technologies, Inc. 2103 East 33rd Street, Erie, PA 16510-2529. Tel: (814) 899-6390. Fax: (814) 899-7117. E-mail: info@beaumontinc.com. Web www.beaumontinc.com.

MARTIN THOMAS, INC.

Martin K. Pottle, APR

(401)-245-8500

E-mail: contact@martinthomas.com