Micropen Technologies Applies Conductive Features to Solvay's Radel® PPSU for Medical Device Uses

Material and Process Deliver Unique Functionality in Spinal Therapy System

ALPHARETTA, Ga., March 31, 2011 - Micropen Technologies Corp. has successfully used its unique Micropenning® direct printing process to apply patterned conductive and dielectric thick film coatings onto a disposable medical device component made from Radel® polyphenylsulfone (PPSU) resin from Solvay Advanced Polymers, LLC. It was critical that the disposable component, part of a unique spinal therapy system, form a conductive electrode that was highly reliable both electrically as well as mechanically. The marrying of Radel® PPSU and Micropenning® technology gives medical device OEMs a new and innovative option over traditional metal and plastic solutions to build electrically conductive features onto complex parts.

"We subjected the Radel® PPSU component to considerable chemical abuse and high heat, and the material stood up to our process and maintained the mechanical properties that were critical to the application," said Dr. William Grande, Vice President of Research and Business Development for Micropen Technologies. He noted that the project team tested and rejected a wide range of materials before examining PPSU. "We had never worked with sulfone polymers before, but Radel® provided great film adhesion and biocompatibility," said Dr. Grande. "We are intrigued by the possibilities of using other Solvay medical polymers."

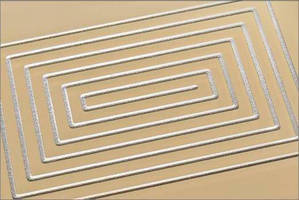

Micropenning® is a "Direct Write" technology that combines precision motion control with the ability to dispense flowable materials - typically thick film polymeric inks - in a designed pattern onto a surface with high accuracy and fine line widths down to 50 microns. Micropenning® is particularly suited to applications involving highly three-dimensional objects and multiple functional materials, a common scenario for medical devices requiring electrical or electronic components, radiopaque markers, and drug dosing.

In the case of the disposable electrode, a conductive silver ink is deposited on the exposed surface of an injection molded Radel® PPSU component. The intricate, three-dimensional part is approximately 9 inches long, 0.25 inches wide, and highly variable in thickness. During the Micropenning® process, the Radel® PPSU component is subjected to a wide range of solvents, UV radiation, and temperatures up to 150ºC (302°F). In clinical use, the disposable electrode's flexibility and exceptional fracture strength enable it to withstand repeated bending.

Radel® PPSU has excellent chemical resistance and withstands repeated autoclaving - up to 1,000 cycles - while maintaining its toughness and impact resistance. The material is a super-tough transparent thermoplastic with a heat distortion temperature (HDT) of 207°C (405°F). It is inherently flame retardant and is resistant to bases and other chemicals. Solvay Advanced Polymers is a global leader in the development of sulfone polymer technology, launching Udel® polysulfone nearly 45 years ago.

About Micropen Technologies Corp.Founded in 1982 and well known for its Ohmcraft line of resistor solutions, Micropen Technologies Corp. is uniquely positioned as the leader in the precise application of materials to surfaces. This enables product designers and materials formulators to develop breakthrough products in the medical device, biomedical, and electronic markets. Micropen Technologies is headquartered in Honeoye Falls, N.Y. For more information, visit www.micropen.com.

About Solvay Advanced Polymers

Solvay Advanced Polymers, LLC produces more plastics with more performance than any other company in the world. This gives design engineers worldwide more ways to solve top design challenges in automotive, medical, electronics, aerospace and other demanding industries. Learn more at www.solvayadvancedpolymers.com.

Solvay is an international industrial Group active in Chemistry. It offers a broad range of products and solutions that contribute to improving quality of life. The Group is headquartered in Brussels and its companies employ 17,000 people in over 40 countries. In 2010, its consolidated sales amounted to EUR 7.1 billion. Solvay is listed on the NYSE Euronext stock exchange in Brussels (NYSE Euronext: SOLB.BE - Bloomberg: SOLB.BB - Reuters: SOLBt.BR). Details are available at www.solvay.com.

Press Contact:

Joseph Grande

413.684.2463

solvayap.press@solvay.com