Microelectromechanical Systems (MEMS)

MEMS Cavity Seal Integrity

Elk Grove Village, IL, May 12, 2010 -- As part of its bonded wafer inspection technology, Sonoscan has recently demonstrated acoustic imaging of defects in the seal that surrounds and protects the cavities in MEMS devices.

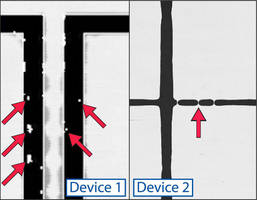

The defects most frequently take the form of voids (Device 1 above) within the seal, which may be direct Si, metallic, glass or polymer, depending on the reliability level of hermetic seal required as per SEMI MS8-0309. In some locations on a wafer the seal may be breached (Device 2 above). Another frequent defect is delamination of the seal from one or both substrates, the result of poor wetting or contamination during fabrication.

The defects are risky because thermal and mechanical stresses can cause them to grow until they cause a leak in the seal and the subsequent loss of the desired atmosphere within the cavity. The seal prevents outside particles, gases and humidity from reaching the cavity. Humidity, for example, can result in freezing up of moving parts within the cavity.

Defects in the seal may be only a few tens of microns in diameter and of sub-micron thickness, but can be imaged by Sonoscan's C-SAM® systems because they represent a gap that reflects >99.99% of the VHF/UHF ultrasonic pulse.

In production, a percentage of MEMS devices may be imaged with C-SAM acoustic micro imaging systems in order to verify that process parameters are preventing the formation of voids. Where high reliability is essential, as in mil/aero or medical MEMS, 100% of devices may be inspected.

For more information on inspection services, contact SonoLab® manager Ray Thomas at 847.437.6400 x 245. For more information on inspection systems contact technical marketing manager Steve Martell at 847.437.6400 x 240.

About Sonoscan®: Sonoscan is the leading developer and manufacturer of acoustic microscopes and sophisticated acoustic micro imaging systems, widely used for nondestructive analysis of defects in industrial products and semiconductor devices. For over 30 years, Sonoscan's attention to customer needs and investment in R&D has created systems that set industry standards for speed and accuracy. Key products include C-SAM® systems for off-line and laboratory analysis and FACTS2(TM) for automated production inspection.

Through its SonoLab division Sonoscan applications engineers, with experience totaling more than two centuries in acoustic microscopy, assist hundreds of customers annually in solving materials problems and quality control issues. SonoLab operates applications testing laboratories in multiple global locations to serve the inspection needs of customers that do not have their own capability.