Delcam to Show New CAM Range at EASTEC

Share:

Delcam will be promoting its full range of CAM software and services at EASTEC 2010 exhibition held May 25 - 27, 2010

o Eastern States Exposition

West Springfield, Massachusetts

Programs on show will include the new Delcam for SolidWorks software, plus the 2010 releases of PowerMILL for high-speed and five-axis machining, FeatureCAM for feature-based programming, PartMaker for Swiss-type lathes and turn-mill equipment, and ArtCAM for engraving and routing.

Together, these programs comprise the world's most comprehensive range of CAM software from a single suppler. This broad coverage is one of the reasons why Delcam is consistently ranked as the world's leading specialist supplier of NC software and services by US analysts Cimdata. It means that large companies can source all of their CAM requirements from a single supplier, while smaller organizations can be sure that they can obtain exactly the software they need, rather than having to compromise on a less-than-ideal solution.

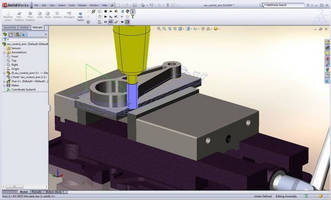

Delcam for SolidWorks marks a new direction for Delcam. Previously, the company has supplied all of its machining software as stand-alone systems that can be linked to any CAD program. In contrast, Delcam for SolidWorks is fully integrated into the SolidWorks environment so that the program looks and behaves like SolidWorks. It offers full associativity so that any changes in the CAD model will be reflected automatically in the toolpaths.

Delcam for SolidWorks is based on proven machining algorithms that are already used by more than 30,000 customers around the world. The software offers PowerMILL's exceptional speed of toolpath calculation, plus all of advanced strategies to increase productivity, maximize tool life and give immaculate surface finish, even when cutting the hardest, most challenging materials.

At the same time, Delcam for SolidWorks has the same strong focus on ease of use as FeatureCAM, including all of the knowledge-based automation that makes it so consistent and reliable. Most importantly, the software will include FeatureCAM's Automatic Feature Recognition system which automatically extracts detailed feature information from the SolidWorks model. Once the features have been identified, Delcam for SolidWorks undertakes automatic selection of cutting tools, machining strategies, and feeds and speeds, to complete the programming operation.

As well as producing Delcam for SolidWorks, Delcam's development team, the largest in the CAM industry, has been working on its established CAM programs. The new release of PowerMILL is based on 64-bit technology, removing the memory limitations of 32-bit computers to give faster toolpath generation. The 2010 version also continues to improve user productivity by extending the application of the latest background-processing and multi-threading technologies available in recent hardware. More than 50 other major enhancements have been added to give faster and easier generation of highly efficient toolpaths for three- through five-axis milling.

The 2010 version of FeatureCAM also includes enhancements across the full range of functionality, from 2D drilling and wire EDM, to five-axis milling and mill-turn operations. In addition to changes to allow the use of hardware developments, improved algorithms have been introduced to speed up the editing of features and to reduce the time needed to switch between machine-tool set-ups. More efficient handling of stock models reduces the memory required for calculations and so enhances performance still further.

Major highlights of the new release of PartMaker include the ability to perform five-axis simultaneous milling on multi-axis lathes, more powerful milling functionality, enhanced grooving routines, faster tool path creation and better programming of thread whirling. PartMaker 2010 also features the option for a direct interface to PowerMILL, allowing toolpaths to be imported into PartMaker, manipulated and synchronized for optimum machine performance, and then simulated and post-processed directly from that working environment.

A great deal of underlying technology from PowerMILL has been incorporated into ArtCAM 2010, including the latest multi-threading technology and greater flexibility to edit toolpaths. New machining options include a new combination technique of roughing with an end-mill coupled with V-bit carving, and a "raised-round" command to generate this machining option directly from vector artwork.

For More information contact Mary Shaw 1 - 877 Delcam - 1 ext 232 mes@delcam.com