CiDRA's Supplier Quality System and Stahlin's Non-Metallic Enclosures - Partnering on Quality

Share:

Today, corporations know partnerships are the supply chain's lifeblood. As needs for the businesses increase on the buy side, demands on suppliers also increase, as they are asked to continuously reduce costs, improve quality, and develop new processes and products. CiDRA and Stahlin have been effectively covering these demands, and their partnership is based on an important attribute - quality. CiDRA's Supplier Quality System provides the backbone for critical components sourced for CiDRA's SONARtrac® system and for the successful partnership with suppliers like Stahlin.

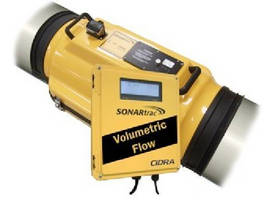

CiDRA is headquartered in Wallingford, Connecticut with an increasing number of international offices. CiDRA's patented SONARtrac® flow technology has established itself as a new class of industrial flowmeter, utilizing measurement principles that are distinct from all other flowmeter technologies operating today and is ideally suited for measuring flow in difficult slurry applications within the energy and natural resource industries. CiDRA has been aggressively developing various service offerings related to flow management and assurance and overall plant monitoring and process optimization in mining, oilsands, power generation, and chemical management in pulp and paper applications. CiDRA products and services are being used by over 350 customers in over 30 countries.

CiDRA's Supplier Quality System was established over 10 years ago, to ensure high quality supplier relationships beyond the traditional methods. The CiDRA Supplier Quality System requirements states that all suppliers or potential suppliers shall maintain a system that meets CiDRA's set of rigorous requirements and suppliers will be evaluated to an extent for which the requirements are met. These requirements will be conveyed to suppliers or potential suppliers during the quotation and purchase order process. The quality of all CiDRA designed parts, subassemblies, and special processes shall be governed by this document. The goal is to ensure all the products provided to CiDRA meet the companies' and their customers' needs.

When CiDRA evaluated Stahlin's non-metallic enclosure DiamondShield ® product line for use with the SONARtrac system, a list of critical needs for the product line needed to be reviewed. CiDRA's requirements were focused on a NEMA-4X rating, cost, weight of enclosure, UV protection, a superior panel management system and available color options and customization.

"The enclosure must be able to withstand extreme weather and temperature fluctuations, be resistant to chemical and corrosion, resist discoloration from extreme sunlight and seal out dust and debris," stated Ed Wojtowicz, CiDRA Corporate Services. "Since these enclosures would be installed throughout the world, they would have to face a wide variety of adverse weather and hazardous conditions and must withstand these challenges."

"Overall, the Stahlin DiamondShield ® enclosure has met all of our requirements and has been extremely reliable in the field. The enclosures have been placed in a wide range of industries worldwide, across all types of extreme conditions, and have performed without a failure. The enclosure has provided excellent protection to the internal instrumentation, providing the user with reliable monitoring of pipe flow measurement," Wojtowicz continued, "In addition, all of Stahlin's enclosures are molded from SolarGuard®, a patented sheet molded compound formulation that claims to provide superior molded-in UV resistance. We found those claims to be true and consequently are now successfully using the Stahlin enclosures to protect our control systems from UV damage as well as other environmental threats such as corrosion and moisture. In turn this protects the reputation and image of our products."

Stahlin's DiamondShield ® product line has proven its value to CiDRA and lived up to the requirements originally established with CiDRA's Supplier Quality System. As a result, both CiDRA and Stahlin have benefited from this success. "Product aesthetics are very important to CiDRA. We believe the changes Stahlin made to some manufacturing processes internally that checked for the look of the product, have benefited other customers with similar concerns," stated Maria Lamorey, Product Specialist, Stahlin Non-Metallic Enclosures. "In addition, we are molding the DiamondShield ® in yellow and blue for CiDRA. It has been nice to observe our product showcased in these colors on their equipment."

CiDRA's Supplier Quality System for components sourced for SONARtrac, partnered with Stahlin's DiamondShield ® Enclosures is a proven success for both companies. Today, CiDRA has deployed a high quality enclosure that has withstood the demanding environments they require and Stahlin has gained visibility for their high quality fiberglass enclosures throughout the world through the use of their product on this very unique product line - the SONARtrac System.

For more information on CiDRA visit: www.cidra.com

For more information on Stahlin visit: www.stahlin.com

Chase Gregory

J4 Communications

407-340-8573