Abrisa Technologies Indium Tin Oxide (ITO) and Index-Matched (ITO) Optical Coatings are Electrically Conductive and Optically Transparent

Abrisa Technologies can provide both Indium Tin Oxide (ITO) and Index-Matched Indium Tin Oxide (IMITO) thin film optical coatings for a wide variety of optics applications. The durable coatings provide for an electrically conductive glass surface that offers high optical transparency with transmittance levels that can be in excess of 99%. Common wavelengths for the coatings are 400 to 700 nm (visible) and 1500 to 1650 nm (near IR). A variety of sheet resistances such as 5 ohms per square for shielding applications and higher values for heater applications can be provided depending upon the particular application requirement. Glare reducing broadband anti-reflective coatings can also be applied to the glass substrate along with the ITO/IMITO coating.

ITO/IMITO coatings are commonly used to shield electromagnetic interference (EMI) while transmitting a high level of visible light, as heater windows for outdoor use, and in electronic devices such as LCDs and switches. The coatings can be applied to a wide variety of commercial glass such as soda lime float glass, borosilicate and aluminosilicate glass as well as other technical substrates such as ceramic, and fused silica.

Typical applications for ITO/IMITO coated glass include:

Liquid crystal, flat panel, plasma, and touch panel displays

Heated and anti-static windows

Transparent EMF, EMI EMC, RFI, and HF shielded glass

Instrumentation

Electronic displays

GPS systems

Outdoor displays

Heater panels

ITO and IMITO coatings from Abrisa Technologies are resistant to flaking, peeling, cracking, delaminating, and crazing. The coatings can be applied to substrate sizes as small as 0.25" and up to a substrate size as large as 27" in diameter. The minimum substrate thickness that Abrisa Technologies can provide ITO coatings for is 7 µm while the maximum substrate thickness that can be coated is up to 4".

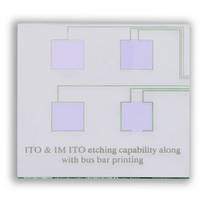

Custom fabrication of ITO/IMITO coated glass can include the addition of Bus Bars, custom edge treatments, opposed drilling of holes, custom cutting, chemical strengthening, screen printing, wire bonding, and more, for a fully integrated optics solution.

All ITO/IMITO coatings are applied via an ion assisted physical deposition process which provides an extremely uniform film while virtually eliminating macro particle content.