Additive Manufacturing Systems

3D Systems Celebrates 10th Anniversary of Groundbreaking Conjoined Twin Separation Surgery

- August 4th marks 10th anniversary of successful surgery to separate conjoined twins Carl and Clarence Aguirre, joined at the head

- Successful surgery leveraged complex SLA® 3D-printed models of the twins' heads to enable surgical planning, practice and guidance created by 3D Systems' Medical Modeling

ROCK HILL, S.C. — 3D Systems (NYSE:DDD) announced today the 10th anniversary of the successful completion of groundbreaking conjoined twin separation surgery that leveraged SLA® 3D-printed models from 3D Systems' Medical Modeling.

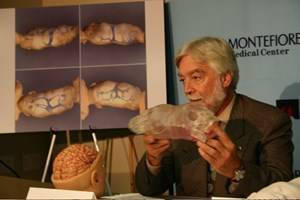

On Wednesday, August 4, 2004, surgeons at Children's Hospital of Montefiore, Bronx, NY, did what many believed to be impossible - they completed a successful separation surgery of conjoined twins Carl and Clarence Aguirre, joined since birth at the head. The complex surgery was carried out through a series of four separate operations, after a year of planning and practice. Surgeons credit advanced planning with Medical Modeling's anatomical modeling services in helping to make this surgery a success.

The surgical team, led by pediatric neurosurgeon Dr. James T. Goodrich, decided on a unique "staged" surgical approach. From October 2003 until August 2004, a series of four surgeries were used to gradually separate the vital blood vessels of the brain joining Carl and Clarence. Medical Modeling provided 3D-printed anatomical models prior to each stage of surgery up to and including the final separation procedure. The advanced models were created from the twins' CT and MRI data using 3DS' ClearView® material to print life-size selectively-colored Stereolithography representations of the bone structure, with all critical brain blood vessels highlighted.

"The surgeons reported that the 3D-printed anatomical models were a key part of the surgical planning for this incredibly complex case and contributed to its positive outcome," said Andy Christensen, Vice President of Personalized Surgery and Medical Devices, 3DS. "For more than a decade, 3D printed surgical models and virtual surgical planning services have changed the way surgeries are performed and in cases like this are dramatically impacting patient lives."

The twins will be making an appearance at Montefiore Medical Center, alongside the teams who assisted in the surgery, to celebrate the anniversary on August 4, 2014.

Today, as the surgical team and contributors are celebrating the twins' progress, 3DS advanced SLA 3D printers, are already in-use by the leading global hearing aid, dental, orthodontic and medical device companies producing tens of millions of medical devices annually.

3DS' Medical Modeling continues to develop world-class clinical capabilities in Virtual Surgical Planning (VSP®), guiding and instrumenting of complex personalized surgical procedures as well as production at scale of 3D-printed implants and medical devices. Last week, 3DS announced that it is acquiring Simbionix, the industry leader in 3D virtual reality surgical simulation and training. Simbionix brings 60+ interventional procedures across 8 specialties through 16 simulation platforms to 3DS' expanding healthcare portfolio, creating an unrivaled digital thread for medical procedures that extends from the training room to the operating room.

View a video explaining the surgery for the Aguirre twins.

Learn more about 3DS' commitment to manufacturing the future at 3DSystems.com.

About 3D Systems

3D Systems is a leading provider of 3D printing centric design-to-manufacturing solutions including 3D printers, print materials and cloud sourced on-demand custom parts for professionals and consumers alike in materials including plastics, metals, ceramics and edibles. The company also provides integrated 3D scan-based design, freeform modeling and inspection tools and an integrated 3D planning and printing digital thread for personalized surgery and patient specific medical devices. Its products and services replace and complement traditional methods and reduce the time and cost of designing new products by printing real parts directly from digital input. These solutions are used to rapidly design, create, communicate, prototype or produce functional parts and assemblies, empowering customers to manufacture the future.

Leadership Through Innovation and Technology

-- 3DS invented 3D printing with its Stereolithography (SLA) printer and was

the first to commercialize it in 1989.

-- 3DS invented Selective Laser Sintering (SLS) printing and was the first

to commercialize it in 1992.

-- 3DS invented the Color-Jet-Printing (CJP) class of 3D printers and was

the first to commercialize 3D powder-based systems in 1994.

-- 3DS invented Multi-Jet-Printing (MJP) printers and was the first to

commercialize it in 1996.

-- 3DS pioneered virtual surgical planning (VSP) and 3D printed medical

modeling and devices with services that benefit humanity the world over.

Today its comprehensive range of 3D printers is the industry's benchmark for production-grade manufacturing in aerospace, automotive, patient specific medical device and a variety of consumer, electronic and fashion accessories.

More information on the company is available at www.3DSystems.com.

Â

Contact:Â

Media Contact:

Alyssa Reichental

Email: Press@3dsystems.com