NETZSCH Pumps North America, LLC

Exton, PA 19341

Laboratory Classifier features gas flow volume of 29 scfm.

High Dispersion Air Classifier, Model CFS 5 HD-S, features ConVor constant radial velocity classifier wheel. Suited for low volume and/or high value materials, unit guarantees optimal classifying results on laboratory scale. Accessible design and removable parts facilitate cleaning of machine. Complete classifier system can be provided with feeder, cyclone, filter, blower, and control panel...

Read More »

Drying Device dries all types of slurries.

Machine combines mechanical dewatering system and thermal drying device in one compact unit. Cake drying device is constructed with polypropylene membrane filter plates, which can be retrofitted for existing presses. Drying system is available in side bar and overhead beam designs for semi-automatic or fully automatic presses. Features include honeycombed, insulated heating elements and suction...

Read More »

Mills are sized for laboratory grinding.

Non-metal MiniCer and MiniPur are part of MiniZETA laboratory-sized equipment line. MiniCer is manufactured with zircon-oxide wetted components, while MiniPur has polyurethane wetted components. Both machines feature adjustable position chamber and are capable of handling batch sizes down to 250 mL, with chamber volume of 150 mL. Optimized for circulation or discrete pass milling, products can...

Read More »

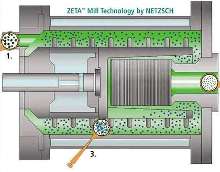

Bead Mills reduce particles to submicron sizes.

Horizontal Agitator Bead Mills grind particles with initial fineness of 1-20 micrometers down to 40-200 nanometers. In enclosed vessel filled with grinding media, agitator shaft activates media, creating shearing and impacting forces. Rotation of agitator imparts energy to surrounding media. Forces either fracture, tear, or crush particulate. Dynamic Cartridge Media Separator retains media in...

Read More »

Mixing System is suitable alternative to vacuum feeding.

Able to achieve homogeneous pre-dispersion results with precise, reproducible qualities, Y-Mix(TM) disperser incorporates controlled process environment where finely dispersed powders come in contact with liquid surface and are wetted under shear. Product offers dust and emission-free dispersion within completely enclosed process chamber and is not sensitive to large particles or foreign objects...

Read More »

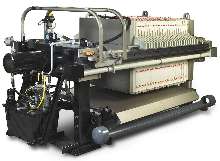

Filter Press separates solids from liquids.

Available in plate and frame, recessed chamber, or membrane configurations, WP Series produces solid filter cakes for unlimited number of dewatering applications. Frame design includes rotating pin joint connectors for even distribution of hydraulic forces and plate shifter with fully automatic, positive parallel tracking, and accurate plate alignment. Additional offerings include pump systems,...

Read More »Universal Mill CUM performs ultra-fine sugar grinding.

NETZSCH-CONDUXÃ-® Universal Mill CUM allows precise control of particle size distribution and provides efficient processing of materials from 50-2000 Ã-µm. Unit also handles temperature-sensitive materials due to efficient internal air flow. Depending on material to be processed and desired end product fineness, interchangeable grinding elements enable adaptation to differing needs....

Read More »Universal Grinding Mill suits pharmaceutical applications.

GMP Pharmaceutical Universal Mill CUM 150 utilizes interchangeable grinding elements to produce desired end product fineness. Able to adapt to differing needs, unit offers flexibility to allow for efficient processing of materials between d50 = 10 Ã-µm and d50 = 100 Ã-µm. All internal/external surfaces are radiused and finished to Ra = 0.4 microns with optional electropolishing....

Read More »

Disperser suits sanitary applications.

Suited for low- to high-viscosity dispersion and high-shear dispersion/low-speed agitation, totally enclosed, automated pre-mixing MASTERMIX(TM) Disperser PMD-VC provides contamination-free working environment. Product, used for mixing and dispersing solids into liquid, is designed for batch sizes from 50-10,000 liters and larger. Self-contained system incorporates high-shear disperser, low-speed...

Read More »

Deaerator suits personal-care and cosmetic industry.

Deaerator Mill continuously removes trapped air or gas bubbles from various liquid products over wide range of viscosities. Totally enclosed, self-contained system can process up to 5000 kg per hour and can de-gas small amounts from portable vessels, as well as large batches in continuous operation. It requires no additional feed or discharge pumps and can be coupled in-line with filling...

Read More »NETZSCH Proudly Celebrates 50th Anniversary of North American Operations

Family-owned global company develops products and technologies to handle challenging applications and reduce life cycle costs NETZSCH Pumps North America, LLC, experts in solutions designed specifically for difficult pumping applications, announces it is celebrating its 50th anniversary in business. As a mid-sized, family-owned German company, NETZSCH manufactures machinery and instrumentation...

Read More »NETZSCH Pumps North America, LLC Announces Enpro, Inc. as Their Industrial Partners in Missouri, Kansas and Southern Illinois

NETZSCH, the world’s largest manufacturer of Progressing Cavity Pumps, Rotary Lobe Pumps and Multiple Screw Pumps, is pleased to announce the signing of Enpro, Inc. in Addison, Illinois as the new NETZSCH Industrial Representative for Missouri, Kansas and Southern Illinois for Progressing Cavity Pumps, Rotary Lobe Pumps and Grinders. Enpro, Inc. will represent NETZSCH in all industrial markets...

Read More »NETZSCH Announces Membership in Star Pump Alliance

Star Pump Alliance facilitates pump searching for professional users Exton, PA – NETZSCH Pumps North America announces its membership in the Star Pump Alliance, an organization that works to assist professional users of pumps in selecting pump technology tailored to fit their specific applications. NETZSCH Pumps North America is proud to be able to offer their expertise and experience in...

Read More »NETZSCH Pumps North America, LLC Announces Brian Johnson, New Regional Sales Manager for the Central Region

Exton, PA - 10/1/2017 - NETZSCH PUMPS NORTH AMERICA, LLC (Exton, PA) has expanded its sales force by hiring Brian Johnson as the Regional Sales Manager for the Central Region. He will be responsible for supporting our Industrial and Municipal Distributors / Representative in the states of Michigan, Indiana, Kentucky, southern Ohio (municipal only), Illinois, Wisconsin, Missouri, Kansas, Nebraska,...

Read More »NETZSCH Canada, Incorporated Announces Norman Zombor, Western Regional Manager, Oil and Gas

NETZSCH CANADA Incorporated (Barrie, ON) recently expanded its sales force by hiring Mr. Norman Zombor as Western Regional Manager for the Oil and Gas market. He is responsible for supporting and promoting NETZSCH products to distributors, end-user customers and EPC customers in of Alberta and British Columbia. Mr. Zombor comes to us with a CET in mechanical engineering and a career of increasing...

Read More »NETZSCH Pumps North America, LLC Announces Lucas Love, Southeast Region Sales Manager

NETZSCH PUMPS NORTH AMERICA, LLC (Exton, PA) recently promoted Lucas Love to Regional Sales Manager for the Southeast Region of the US. He is responsible for supporting our Industrial and Municipal sales channel partners in Florida, Georgia, Alabama, South North Carolina and Eastern Tennessee. Mr. Love will be relocating to Atlanta, Georgia later this year to better serve this region. NETZSCH is...

Read More »2014 Global Product Leadership Award in Progressing Cavity Pumps for Oil and Gas Goes to NETZSCH

Award presentation by Frost Sullivan NETZSCH proudly announces that for the second time since 2011, it will be presented with a highly appreciated, best practices award by Frost Sullivan, the U.S.-based growth partner-ship company. In its motivation statement, Frost & Sullivan explains that the 2014 Global Product Leadership Award in Progressing Cavity Pumps for Oil and Gas was issued by...

Read More »NETZSCH Pumps North America, LLC Announces Todd Rogers, Upstream Oil & Gas Regional Manager for Texas

NETZSCH Pumps North America, LLC Announces Todd Rogers, Upstream Oil Gas Regional Manager for Texas Exton, PA – NETZSCH PUMPS NORTH AMERICA, LLC (Exton, PA) recently named Todd Rogers as the Regional Sales Manager in charge of sales and operations for our Sales and Service Center in Odessa, Texas, reporting to the Business Field Oil & Gas Upstream Manager, Lindy Dekle. Mr. Rogers will be...

Read More »NETZSCH Pumps North America, LLC Announces Municipal Valve & Equipment Company as their Municipal Partners in Oklahoma and Texas

NETZSCH, the world’s largest manufacturer of Progressing Cavity Pumps, Rotary Lobe Pumps and now Multiple Screw Pumps, is pleased to announce the signing of Municipal Valve Equipment Company in Plano, Texas as the new NETZSCH Municipal Representative for Texas and Oklahoma for Progressing Cavity Pumps, Rotary Lobe Pumps and Grinders. MVE will represent NETZSCH in all municipal markets in this...

Read More »NETZSCH Pumps North America, LLC Announces R.F. MacDonald Company as their Industrial Partners in Southern California

NETZSCH, the world’s largest manufacturer of Progressing Cavity Pumps, Rotary Lobe Pumps and now Multiple Screw Pumps for the Industrial Market, is pleased to announce the signing of R.F. MacDonald Company as their distributor in Southern California to service the Industrial marketplace in this region. R.F. MacDonald Co. will represent NETZSCH in all industrial markets as well as Oil and Gas...

Read More »