Van der Graaf Inc.

Shelby Township, MI 48315

Van Der Graaf Inc. Offers Swap Program for Drum Motors Used in Wash-Down Applications

Van der Graaf, Inc., the leading manufacturer of drum motors for a broad range of material handling applications, has recently offered a SWAP Program. The program, initially intended for food handling wash-down applications allows customers to send their drum motors to any Van der Graaf facility and the units will be upgraded to the latest design and/or exchanged for the newest models for the...

Read More »

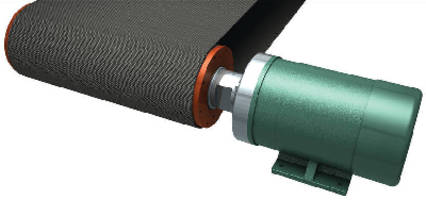

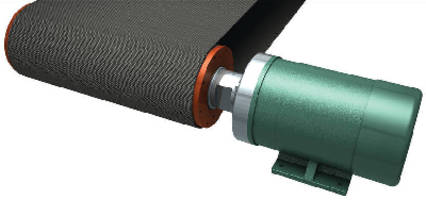

Drive Roller combines efficiency, safety, and flexibility.

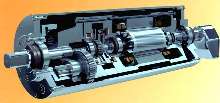

Available in 6.5 and 8.5 in. dia, internally driven Cross Drive(TM) has no external moving parts and thereby eliminates possibility of employee injury and/or product contamination. Transfer of power from motor's drive shaft to drive roller's outer shell is 96% mechanically efficient, made possible via hardened-steel, precision-cut gear assembly. Latter is housed in sealed conveyor drive roller...

Read More »

Drum Motor meets demands of corrosive applications.

Suitable for medium- and heavy-duty applications, conveyor motor features rugged construction for bulk handling applications. Hermetically sealed, it is protected from water, dirt, dust, grit, and chemicals. Motor features internal AGMA 12 rated high alloy steel gears with inverter that runs at 96% efficiency. Available in diameters from 3.9-19.69 in., and face widths from 10-63 in., drive motors...

Read More »

Drum Motor Drives feature internal braking.

Drives include RTM electromechanical brake for up to 25 starts and stops per minute. Clutch brake (CBTM) eliminates in-rush of start-up current and provides up to 80 starts and stops per minutes. Horsepower range is from 0.50 to 20.0 hp, and standard face widths range from 16.73 to 39.38 in., depending on motor size. Drum speeds are fixed and range from 28 to 1369 ft/min to match unlimited number...

Read More »

Drum Motor meets MHSA requirements.

Explosion proof 30 hp motor provides safe operation when driving belt conveyors in applications that have potential for fire or explosion, such as mining, feed and grain, sugar mills, and fertilizer plants. Low-profile, 12.5 in. dia motor has heavy-duty bolts; secondary o-ring seal for complete hermetic sealing; standard face width of 51 in.; and cast iron shell, shaft, and end cap. Drum speed is...

Read More »

Drum-Motor Lagging extends belt life.

Drum-motor lagging options and motor-face patterns improve belt traction and tracking in concrete and aggregate operations. Laggings are available in smooth or patterned rubber and urethane or metal. Metal-tread laggings eliminate oil build up in asphalt recycling. Laggings complement standard parabolic, machine-crowned shell that tracks on all points of contact. They ensure even belt wear and...

Read More »

Clutch Brake suits high-indexing conveyor applications.

Clutch brake allows internal drum motor to run continuously and engages pulley shell only when conveyor movement is desired. It provides indexing speeds up to 80 starts and stops per min. 8 1/2 in. dia drum motor, equipped with clutch brake, eliminates in-rush of start-up current. It operates as either normal unit, idler unit, or brake unit. Horsepower range is from 0.50 to 5.50 hp. Drum speeds...

Read More »

Drum Motor Drives drive food conveyors.

Internally powered drum motors are available with USDA Dairy 304 or 316 stainless steel shell, shafts and end flanges that resist corrosion and contamination prohibited in food industry. Each motor is filled with food grade oil and hermetically sealed, making it suitable for applications requiring daily high-pressure washdown and acid or alkaline power washings. Drives have sprockets for driving...

Read More »Van Der Graaf Inc. Offers Swap Program for Drum Motors Used in Wash-Down Applications

Van der Graaf, Inc., the leading manufacturer of drum motors for a broad range of material handling applications, has recently offered a SWAP Program. The program, initially intended for food handling wash-down applications allows customers to send their drum motors to any Van der Graaf facility and the units will be upgraded to the latest design and/or exchanged for the newest models for the...

Read More »

Drive Roller combines efficiency, safety, and flexibility.

Available in 6.5 and 8.5 in. dia, internally driven Cross Drive(TM) has no external moving parts and thereby eliminates possibility of employee injury and/or product contamination. Transfer of power from motor's drive shaft to drive roller's outer shell is 96% mechanically efficient, made possible via hardened-steel, precision-cut gear assembly. Latter is housed in sealed conveyor drive roller...

Read More »

Drum Motor meets demands of corrosive applications.

Suitable for medium- and heavy-duty applications, conveyor motor features rugged construction for bulk handling applications. Hermetically sealed, it is protected from water, dirt, dust, grit, and chemicals. Motor features internal AGMA 12 rated high alloy steel gears with inverter that runs at 96% efficiency. Available in diameters from 3.9-19.69 in., and face widths from 10-63 in., drive motors...

Read More »

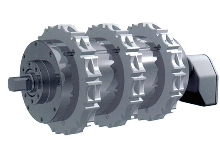

Drum Motor Drives feature internal braking.

Drives include RTM electromechanical brake for up to 25 starts and stops per minute. Clutch brake (CBTM) eliminates in-rush of start-up current and provides up to 80 starts and stops per minutes. Horsepower range is from 0.50 to 20.0 hp, and standard face widths range from 16.73 to 39.38 in., depending on motor size. Drum speeds are fixed and range from 28 to 1369 ft/min to match unlimited number...

Read More »

Drum Motor meets MHSA requirements.

Explosion proof 30 hp motor provides safe operation when driving belt conveyors in applications that have potential for fire or explosion, such as mining, feed and grain, sugar mills, and fertilizer plants. Low-profile, 12.5 in. dia motor has heavy-duty bolts; secondary o-ring seal for complete hermetic sealing; standard face width of 51 in.; and cast iron shell, shaft, and end cap. Drum speed is...

Read More »

Drum-Motor Lagging extends belt life.

Drum-motor lagging options and motor-face patterns improve belt traction and tracking in concrete and aggregate operations. Laggings are available in smooth or patterned rubber and urethane or metal. Metal-tread laggings eliminate oil build up in asphalt recycling. Laggings complement standard parabolic, machine-crowned shell that tracks on all points of contact. They ensure even belt wear and...

Read More »

Clutch Brake suits high-indexing conveyor applications.

Clutch brake allows internal drum motor to run continuously and engages pulley shell only when conveyor movement is desired. It provides indexing speeds up to 80 starts and stops per min. 8 1/2 in. dia drum motor, equipped with clutch brake, eliminates in-rush of start-up current. It operates as either normal unit, idler unit, or brake unit. Horsepower range is from 0.50 to 5.50 hp. Drum speeds...

Read More »

Drum Motor Drives drive food conveyors.

Internally powered drum motors are available with USDA Dairy 304 or 316 stainless steel shell, shafts and end flanges that resist corrosion and contamination prohibited in food industry. Each motor is filled with food grade oil and hermetically sealed, making it suitable for applications requiring daily high-pressure washdown and acid or alkaline power washings. Drives have sprockets for driving...

Read More »