Epoxies Etc.

Cranston, RI 02921-3407

Polyurethane Potting Compound cures in 1 hour.

Designed to cure within 1 hour at room temperature, 20-2183 features 2:1 mix ratio and low viscosity that makes it suitable for use in cable assemblies, potting electronics, molding parts, and encapsulating electronic components. Tough elastomeric material helps assemblies withstand thermal cycling, offers vibration resistance, and imparts low stress on electronic components during cure....

Read More »

Cost Effective Protection for Submersible Components - Urethane Elastomer Series for Underwater and Extreme Weather Applications

The 20-2330 Series of low durometer urethanes, ranging from Shore A 30 to Shore A 90, is perfect for protecting electronic and other components in extreme conditions.Ã- This Series has outstanding resistance to water, good chemical resistance, and provides great electrical insulation.Ã- The products maintain their flexibility over a broad temperature range (from -40Ã-

Read More »Low-Viscosity Epoxy Adhesives offer fast set times.

Setting in 5, 20, and 46 min, respectively, Quick-Set Trio (10-3005, 10-3020, and 10-3046) cure at room temperature. Clear and solvent-free products are suited for bonding plated metals, pewter, glass, wood, ceramic, felt, cement, gem stones, rubbers, plastics, and more. Offered in TriggerBond dual barrel cartridge system or bulk packaging, products meet UL94 HB requirements; resist effects of...

Read More »

Urethane Casting Resin is suitable for prototyping applications.

Providing ABS-like feel and appearance, Mercury-free Type 70-2170 urethane casting resin does not contain TDI or MbOCA, and cures rapidly at room temperature. Low shrinkage and low viscosity properties allow for production of dimensionally stable precision parts. Resin is designed for product development and low volume manufacturing.

Read More »Potting/Encapsulating Compound has water-clear formula.

Designed for applications requiring clarity, semi-flexible 20-2620 is non-yellowing and will not place excess stress on electronic components. This 2-component polyurethane compound offers weather resistance and can be used outdoor applications without exhibiting any degradation. Compound, available in TriggerBondÃ-®, cures at room temperature and has 1:1 mix ratio.

Read More »UV Curable Adhesive targets electronics manufacturing.

One-component 60-7105 adhesive, coating, and potting compound cures within seconds when exposed to UV light. With viscosity of 3,000 cps, product self-levels around intricate electronic designs, can cure in deep sections, and adheres to most substrates. Adhesive is available in pre-packaged syringes, quarts, and gallons.

Read More »Silicone Grease offers thermal conductivity.

Designed to fill wide and narrow gaps, 50-1220 Thermal Interface Material consists of filled silicone grease formulated with combination of filler types. Suited for heat sink and high power applications, one-component product features 0.05% bleed after 24 hr at 200Ã-

Read More »Epoxy Potting Compound has mixed viscosity of 6,700 cp.

Targeted for electronic assembly manufacturers, 2-part 20-3063 epoxy potting and encapsulating compound has 1:1 mix ratio with resin pigmented black and catalyst white for visual indication that products have been properly mixed. It cures at room temperature to 75-80 Shore D hardness, has 45 min pot life, usable temperature range of -40 to 130Ã-

Read More »

Electrically-Conductive Ink bonds to variety of substrates.

One-component, silver-filled, 40-3920 polymer system provides electrically conductive path and bonds to substrates such as kapton, mylar, glass, polyester, and ceramic. With viscosity of 9,000 cps at 25Ã-

Read More »Polyurethane Potting Compound protects electronic SMT parts.

Flexible polyurethane potting and encapsulating resin system 20-2353 imparts no stress on delicate/sensitive electronic surface mount components during cure or when thermal cycled in electronic assemblies. Suited for continuous exposure in wet environments, it does not absorb any moisture and maintains flexibility down to -70Ã-

Read More »Tips and Tricks Videos

A new video has been added to the Epoxies, Etc. Tips and Tricks Video Series; How to Choose the Right Chemistry Formulation. Design engineers have many choices when selecting an adhesive or potting compound. One important decision to make when narrowing down the field of choices is which chemistry to use for a particular application. Epoxies, Urethanes, and Silicones all have their advantages and...

Read More »

Polyurethane Potting Compound cures in 1 hour.

Designed to cure within 1 hour at room temperature, 20-2183 features 2:1 mix ratio and low viscosity that makes it suitable for use in cable assemblies, potting electronics, molding parts, and encapsulating electronic components. Tough elastomeric material helps assemblies withstand thermal cycling, offers vibration resistance, and imparts low stress on electronic components during cure....

Read More »

Cost Effective Protection for Submersible Components - Urethane Elastomer Series for Underwater and Extreme Weather Applications

The 20-2330 Series of low durometer urethanes, ranging from Shore A 30 to Shore A 90, is perfect for protecting electronic and other components in extreme conditions.Ã- This Series has outstanding resistance to water, good chemical resistance, and provides great electrical insulation.Ã- The products maintain their flexibility over a broad temperature range (from -40Ã-

Read More »Epoxies, Etc. Launches New Website February 2013

The New Website Celebrates 25 Years of Business, is User-Friendly and Packed with Information Same URL - New Modern Look! Visitors will find plenty of technical information at their fingertips on Epoxies, Etc.'s new website at www.epoxies.com. The new site features drop down navigation menus, product tables, and other features that make it easy to navigate. Epoxies, Etc. always strives to improve...

Read More »Low-Viscosity Epoxy Adhesives offer fast set times.

Setting in 5, 20, and 46 min, respectively, Quick-Set Trio (10-3005, 10-3020, and 10-3046) cure at room temperature. Clear and solvent-free products are suited for bonding plated metals, pewter, glass, wood, ceramic, felt, cement, gem stones, rubbers, plastics, and more. Offered in TriggerBond dual barrel cartridge system or bulk packaging, products meet UL94 HB requirements; resist effects of...

Read More »Epoxies, Etc. Unveils New Video for the TriggerBond-® Product Line

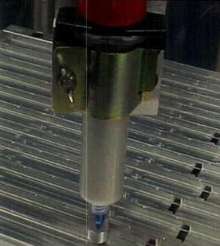

Epoxies, Etc. releases a new video for their TriggerBondÃ-® Product Line - the easy-to-use, no mess system utilizing pre-filled cartridges and a hand-held dispenser. The video can be found on the website at www.epoxies.com in the What's New section or by using the following link: http://www.epoxies.com/video-TriggerBond.htm. This new video explores the reasons why so many customers will only...

Read More »Epoxies, Etc. Unveils New Product Video for Thermally Conductive Potting Compound 50-3150 FR

What makes 50-3150 FR unique as a potting compound? Our new video offers an informative summary of its benefits, and explains why so many product development engineers are specifying this Flame Retardant Potting Compound. The video can be found on our website at www.epoxies.com in the What's New section or by using the following link: http://www.epoxies.com/video-50-3150FR.htm. The 50-3150 FR is...

Read More »

Urethane Casting Resin is suitable for prototyping applications.

Providing ABS-like feel and appearance, Mercury-free Type 70-2170 urethane casting resin does not contain TDI or MbOCA, and cures rapidly at room temperature. Low shrinkage and low viscosity properties allow for production of dimensionally stable precision parts. Resin is designed for product development and low volume manufacturing.

Read More »Epoxies, Etc... Announces a Revision of Its Corporate Brand

CRANSTON, RHODE ISLAND, USA - Epoxies, Etc. continues to enjoy a long and beneficial relationship with our customers and friends. For more than twenty years, we have been steadfast in providing personalized, flexible customer service and customized epoxy, urethane and silicone solutions for many needs. As we continue to diversify and expand our product offerings to meet our customer needs and the...

Read More »Epoxies, Etc Builds New R&D Laboratory

December 2009 - CRANSTON, RHODE ISLAND, USA - Epoxies, Etc is pleased to announce the completion of a new R & D and Quality Control Laboratory. Michael Harrington, President and CEO of Epoxies, Etc stated, The additional laboratory and testing equipment expands our research capabilities and provides needed space for the quality control department. The new equipment in the laboratory increases the...

Read More »