IKA Process

Wilmington, NC 28405

Share:

Powder-Liquid Mixer eliminates excess aeration.

Model MHD provides single-step incorporation and dispersing of solids into liquids. It can be combined with solids feeder, bulk bag unloader, and other equipment to create complete turnkey system for continuous processing. Mixer processes solids concentrations up to 90% as well as extremely viscous liquids. Available in 6 sizes, mixer offers powder feed rates up to 25,000 lb per hour, and nominal...

Read More »

Processing System emulsifies, blends, and homogenizes.

Master Plant(TM) consists of complete processing system for pharmaceutical and cosmetic applications, including vessel, piping, valves, controls, and 2 mixers. Integral spiral agitator and high-shear mixing unit, capable of handling viscosities from 1-100,000+ cps, combine to provide complete mixing, homogenization or dispersion, product transfer, and system cleaning. Available with capacities...

Read More »

Disperser provides scalability and flexibility.

Inline, single-stage Ultra Turrax UTL Model 2000 features rotor/stator to maintain constant tip speed in all sizes, from pilot to full production. Modular design and coarse-to-superfine generators provide flexibility to user. CIP-capable, self-draining unit comes in 7 inlet/outlet sizes, from 1/0.75-8/6 in., with 2-150 hp motors. It mixes emulsions and suspensions, such as sauces, fruit juices,...

Read More »

Conical Mill provides fine particle size reduction.

MKO 2000 Cone Mill(TM) deagglomerates hard to mill materials such as crystals and pigments. Conical rotor and stator of mixing tool uses spiral-shaped teeth for pre-milling and coarse surface coating for fine milling. Combination provides grinding action of stone mill with fluid dispersing capabilities of colloid mill. Mill eliminates need for multiple passes and expensive preprocessing. Cone...

Read More »

Mixing/Dispersing Units are built for specific applications.

Turn-key systems provide continuous or batch mixing, dispersion, and dilution and can be used for combining multiple liquid streams, solids addition, or injection of gases into liquids. Products incorporate DISPAX Reactor high-shear mixer, which is available in 7 sizes with flow rates from 1-1,600 gpm and motors from 2-200 hp. CIP and SIP capable units are provided with vessels, pumps, flow...

Read More »

Disperser provides flexible micro-emulsion production.

DISPAX REACTOR(TM) DR 2000 3-stage inline disperser provides consistent product output with flow rates from 1.5-550 gpm. Three rotor/stator combinations in series produce small droplet or particle size with very narrow distribution. Seven inlet/outlet sizes are available from 1 in./.75 in. to 8 in./6 in., with motors ranging from 2-300 hp. Tip speed remains constant at 4500 fpm. Generators...

Read More »

Research/Development Mixer comes with speed control.

Mixer, with integrated speed control, employs variable frequency drive that mounts directly onto motor. Mixer is operated by hand-held unit, which controls all processing functions. Modular, belt drive system connects AC motor and mixing chambers, allowing each mixer to operate at identical tip speeds. Unit has double mechanical seal, four interchangeable mixing tools, up to three stages, and...

Read More »

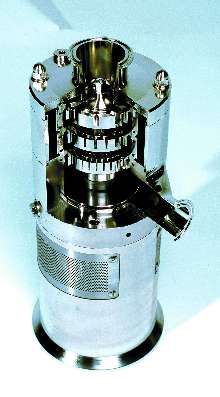

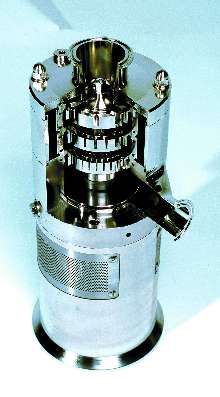

Mixer suits research and development applications.

Process Pilot(TM) features modular, belt drive system that connects servo-motor and mixing chambers, allowing each mixer to operate at identical tip speeds. Double mechanical seal allows use with processes requiring high pressures, or containing highly abrasive solids. All contact surfaces are 316 stainless steel. Process Pilot offers 4 interchangeable mixing tools, 3 stages, and 6 mixing head...

Read More »

Powder-Liquid Mixer eliminates excess aeration.

Model MHD provides single-step incorporation and dispersing of solids into liquids. It can be combined with solids feeder, bulk bag unloader, and other equipment to create complete turnkey system for continuous processing. Mixer processes solids concentrations up to 90% as well as extremely viscous liquids. Available in 6 sizes, mixer offers powder feed rates up to 25,000 lb per hour, and nominal...

Read More »

Processing System emulsifies, blends, and homogenizes.

Master Plant(TM) consists of complete processing system for pharmaceutical and cosmetic applications, including vessel, piping, valves, controls, and 2 mixers. Integral spiral agitator and high-shear mixing unit, capable of handling viscosities from 1-100,000+ cps, combine to provide complete mixing, homogenization or dispersion, product transfer, and system cleaning. Available with capacities...

Read More »

Disperser provides scalability and flexibility.

Inline, single-stage Ultra Turrax UTL Model 2000 features rotor/stator to maintain constant tip speed in all sizes, from pilot to full production. Modular design and coarse-to-superfine generators provide flexibility to user. CIP-capable, self-draining unit comes in 7 inlet/outlet sizes, from 1/0.75-8/6 in., with 2-150 hp motors. It mixes emulsions and suspensions, such as sauces, fruit juices,...

Read More »

Conical Mill provides fine particle size reduction.

MKO 2000 Cone Mill(TM) deagglomerates hard to mill materials such as crystals and pigments. Conical rotor and stator of mixing tool uses spiral-shaped teeth for pre-milling and coarse surface coating for fine milling. Combination provides grinding action of stone mill with fluid dispersing capabilities of colloid mill. Mill eliminates need for multiple passes and expensive preprocessing. Cone...

Read More »

Mixing/Dispersing Units are built for specific applications.

Turn-key systems provide continuous or batch mixing, dispersion, and dilution and can be used for combining multiple liquid streams, solids addition, or injection of gases into liquids. Products incorporate DISPAX Reactor high-shear mixer, which is available in 7 sizes with flow rates from 1-1,600 gpm and motors from 2-200 hp. CIP and SIP capable units are provided with vessels, pumps, flow...

Read More »

Disperser provides flexible micro-emulsion production.

DISPAX REACTOR(TM) DR 2000 3-stage inline disperser provides consistent product output with flow rates from 1.5-550 gpm. Three rotor/stator combinations in series produce small droplet or particle size with very narrow distribution. Seven inlet/outlet sizes are available from 1 in./.75 in. to 8 in./6 in., with motors ranging from 2-300 hp. Tip speed remains constant at 4500 fpm. Generators...

Read More »

Research/Development Mixer comes with speed control.

Mixer, with integrated speed control, employs variable frequency drive that mounts directly onto motor. Mixer is operated by hand-held unit, which controls all processing functions. Modular, belt drive system connects AC motor and mixing chambers, allowing each mixer to operate at identical tip speeds. Unit has double mechanical seal, four interchangeable mixing tools, up to three stages, and...

Read More »

Mixer suits research and development applications.

Process Pilot(TM) features modular, belt drive system that connects servo-motor and mixing chambers, allowing each mixer to operate at identical tip speeds. Double mechanical seal allows use with processes requiring high pressures, or containing highly abrasive solids. All contact surfaces are 316 stainless steel. Process Pilot offers 4 interchangeable mixing tools, 3 stages, and 6 mixing head...

Read More »