The Guyson Corporation of U.S.A.

W.J. Grande Industrial Park

Saratoga Springs, NY 12866

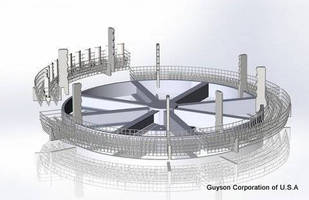

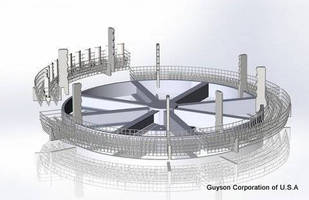

Guysons SP-10 Custom Grit Blaster for Batch Processing Gas Turbine Blades

When a major fortune 500 Aerospace company , who had built their reputation on being dependable , selected Guyson to design and build a custom grit blaster for batch processing gas turbine blades; our engineering team realized that this was something truly unique . Our customer was involved throughout the design of the system and was impressed with how we were able to completely blast the blades...

Read More »

Blast Machine incorporates Fanuc LR Mate 200iC robot.

Measuring 74 x 72 in. with safety-interlocked perimeter enclosure, Model RB-RSSA-6 features 42 in. wide blast chamber that houses single rotary spindle on which interchangeable component-holding fixture is mounted. When blast cycle is initiated, component is rotated at controlled and adjustable speed as single suction-blast gun is directed at target surfaces by 6-axis robot. PLC, to which robot...

Read More »

Blast Machine provides metallurgical shot peening.

Designed for shot peening of machine tool components, Automated Blast Machine features 6-station rotary table mounted on precision cam indexer that steps fixtured components through isolation, peening, and blow-off chambers within abrasion-protected cabinet. At 2 shot peening stations, component-bearing spindles are rotated at controlled speed during timed process cycle. Multiple blast guns are...

Read More »

Grit Blasting Machine prepares surfaces consistently.

Model SP-10 is supplied with cyclone separator and media reclaimer that is lined with abrasion-resistant urethane rubber. Featuring 8 suction-feed blast guns mounted on swing-arm actuator, unit can process circular components up to 40 in. diameter. Blast chamber is 60 x 60 x 60 in. and has automatic sliding doors and motor-driven, 36 in. dia. turntable cart that rotates at controlled and...

Read More »

Rotary Blast Machinery is suited for tall components.

With ability to accommodate parts up to 16 in. length, Model RXS-400EH measures 87 x 30 x 36 in., and features 2-station indexing turntable, each station having rotary spindle with custom-designed fixture to hold one or more components. Programmed automatic blasting process routines are stored and recalled by machine's programmable logic controller. Touch-screen interface provides...

Read More »

Twin Spindle Blast System features automated operation.

Measuring 42 x 30 x 75 in., twin spindle RSSA-6 blast cabinet employs 2 side-by-side spindles for pressure cleaning or surface preparation of IDs and ODs of cylindrical components. Each spindle is topped with mini-turntable fixture that secures component during processing, and 2 pressure-blast nozzles traverse vertically to provide thorough coverage of full part height. Programmed blasting...

Read More »

Dust Collector is suitable for industrial cabinet blasting.

With nonferrous blower assembly powered by 1.5 hp TEFC motor, Model D500 cartridge-type dust collector generates air extraction of 500 Cfm. Measuring 202 x 58 x 87 cm, unit features flame retardant pleated paper filter cartridge and purges dust by reverse pulse cleaning system. Color-coded manometer gauge displays pressure differential between clean and dusty sides of filter while dial-faced...

Read More »

Roller Conveyor System provides abrasive blasting.

Designed for in-line surface preparation of long profiles, rod, bar, and tube materials, Model RC-800 can be used with variety of grit, shot, and bead media to produce different surface textures or finishes. Powered rubber rollers at entry and exit sides of blast cabinet grasp work and steadily feed it at controlled and adjustable speed. Inside finishing enclosure, up to 8 suction-blast guns are...

Read More »Blast Cleaning Machine handles big and heavy components.

Rotary table wheel-blast system, Model GWB-702L features two 10 hp direct-drive blast turbines that deliver 440 lb of media/min and rotate in opposite directions, so blast patterns overlap to completely cover components on machine's table. Measuring 70 in. in diameter, gear-driven turntable is armored with replaceable plates cast in abrasion-resistant alloy and offers capacity of 4,000 lb. Media...

Read More »Blast Cabinet features height-adjustable design.

Suited for manufacturers with multiple users engaged in manual blasting operations, Model 6-AH is usable in blast cleaning, finishing, and surface preparation tasks. Cantilevered design and motorized jackscrew in welded frame enable switch-actuated height adjustment. Available as suction-blast system or with direct pressure media delivery, cabinet has 42 x 30 x 36 in. interior, full-width front...

Read More »

Guysons SP-10 Custom Grit Blaster for Batch Processing Gas Turbine Blades

When a major fortune 500 Aerospace company , who had built their reputation on being dependable , selected Guyson to design and build a custom grit blaster for batch processing gas turbine blades; our engineering team realized that this was something truly unique . Our customer was involved throughout the design of the system and was impressed with how we were able to completely blast the blades...

Read More »Guyson Corporation Acquires Automated Blasting Systems Begins Manufacturing Wet-Blast Machines

The Guyson Corporation of U.S.A. has announced the acquisition of all assets of Automated Blasting Systems, Inc., of South Windsor, CT. ABS has been a premier supplier of wet blast machines to the aerospace, automotive, cutting tool, electronics, metal working and other industries since 1988. The company was formed as a result of purchasing the Ã-'VaquaÃ-¶ product line from The Spadone...

Read More »

Blast Machine incorporates Fanuc LR Mate 200iC robot.

Measuring 74 x 72 in. with safety-interlocked perimeter enclosure, Model RB-RSSA-6 features 42 in. wide blast chamber that houses single rotary spindle on which interchangeable component-holding fixture is mounted. When blast cycle is initiated, component is rotated at controlled and adjustable speed as single suction-blast gun is directed at target surfaces by 6-axis robot. PLC, to which robot...

Read More »Guyson Installs Robotic Blasting Cell

Saratoga Springs, NY - Guyson Corporation has expanded its engineering test laboratory with the addition of a robotic blast system to support application development work on customers' automated blasting projects as well as the company's contract finishing and surface preparation services. Steve Byrnes, President of the blast machinery manufacturing company, unveiled the new equipment at an...

Read More »

Blast Machine provides metallurgical shot peening.

Designed for shot peening of machine tool components, Automated Blast Machine features 6-station rotary table mounted on precision cam indexer that steps fixtured components through isolation, peening, and blow-off chambers within abrasion-protected cabinet. At 2 shot peening stations, component-bearing spindles are rotated at controlled speed during timed process cycle. Multiple blast guns are...

Read More »

Grit Blasting Machine prepares surfaces consistently.

Model SP-10 is supplied with cyclone separator and media reclaimer that is lined with abrasion-resistant urethane rubber. Featuring 8 suction-feed blast guns mounted on swing-arm actuator, unit can process circular components up to 40 in. diameter. Blast chamber is 60 x 60 x 60 in. and has automatic sliding doors and motor-driven, 36 in. dia. turntable cart that rotates at controlled and...

Read More »

Rotary Blast Machinery is suited for tall components.

With ability to accommodate parts up to 16 in. length, Model RXS-400EH measures 87 x 30 x 36 in., and features 2-station indexing turntable, each station having rotary spindle with custom-designed fixture to hold one or more components. Programmed automatic blasting process routines are stored and recalled by machine's programmable logic controller. Touch-screen interface provides...

Read More »

Twin Spindle Blast System features automated operation.

Measuring 42 x 30 x 75 in., twin spindle RSSA-6 blast cabinet employs 2 side-by-side spindles for pressure cleaning or surface preparation of IDs and ODs of cylindrical components. Each spindle is topped with mini-turntable fixture that secures component during processing, and 2 pressure-blast nozzles traverse vertically to provide thorough coverage of full part height. Programmed blasting...

Read More »

Dust Collector is suitable for industrial cabinet blasting.

With nonferrous blower assembly powered by 1.5 hp TEFC motor, Model D500 cartridge-type dust collector generates air extraction of 500 Cfm. Measuring 202 x 58 x 87 cm, unit features flame retardant pleated paper filter cartridge and purges dust by reverse pulse cleaning system. Color-coded manometer gauge displays pressure differential between clean and dusty sides of filter while dial-faced...

Read More »

Roller Conveyor System provides abrasive blasting.

Designed for in-line surface preparation of long profiles, rod, bar, and tube materials, Model RC-800 can be used with variety of grit, shot, and bead media to produce different surface textures or finishes. Powered rubber rollers at entry and exit sides of blast cabinet grasp work and steadily feed it at controlled and adjustable speed. Inside finishing enclosure, up to 8 suction-blast guns are...

Read More »