DME Company LLC

Madison Heights, MI 48071-2330

DME to Display Wide Range of Engineered Hot Runner Solutions at NPE

Learn how DME can be your most complete partner in mold technologies at booth #2803 Madison Heights, Mich. - DME Company, a leading manufacturer of mold technologies, will be presenting a wide range of its hot runner products at NPE 2012, booth #2803. For over 30 years, DME has offered a full spectrum engineered solutions essential for hot runner applications - everything from unitized valve...

Read More »

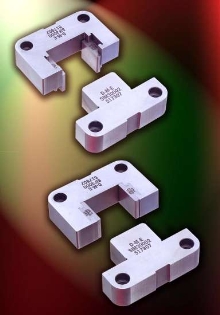

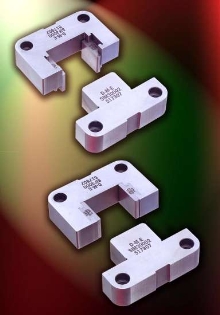

Interlocks feature interchangeable inserts.

Providing accurate alignment of plastic mold halves, Series IN2(TM) INovative INterlocks utilize interchangeable inserts, eliminating need to replace entire side interlock set during maintenance. Graphitic steel inserts are held in place with interference-fit design that retains them when interlocks are installed on mold. There are no coatings, which could peel away under severe conditions.

Read More »

Hot Runner System suits micromolding applications.

Designed for mold bases with tight center-to-center distances, externally-heated Stellar(TM) Hot Runner System works well with commodity and engineering grade resins in high-cavitation applications. Nozzles feature front-loaded design for tips, heaters, and thermocouples. Modular nozzle bodies are interchangeable and can be attached to manifold by threaded or compression connections. Multi-nozzle...

Read More »

Two-Stage Ejectors offer cut-to-length adaptability.

Hardened-Steel, Two-Stage Ejectors offer Bottom Last and Top Last styles in 20, 26, and 32 mm diameters. They control sequence of movement of 2 sets of ejector plate assemblies inside mold's ejector box. Both first stage and second stage strokes can be set independently. Once ejector system is installed, fixed strokes cannot be tampered with or accidentally modified. Latching mechanism eases...

Read More »

Hot Runner Nozzles suit direct gating applications.

Available in 10 lengths from 42-130 mm, Gate-Mate Lite nozzles feature square coil heater and integrated thermocouple. Conductive beryllium copper tip provides precise heat needed for proper gate control. Offered in point-gate or thru-hole tip styles, products have bodiless design that leaves no witness marks on finished molded part. They provide solutions for multi-cavity molds, thin-walled...

Read More »

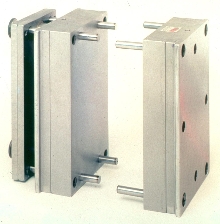

Multi-Parting Line Systems target plastics processors.

Multi-Parting Line (MPL) Systems double cavitation of standard single-face molds. They can be configured as turnkey systems with mold bases, hot runner systems, temperature controllers, and centering devices. Stack Mold Components enable system customization. Dual Mold Carrier enables MPL molding utilizing existing single-face molds. Tandem Molding employs 2 mold faces with staggered processes,...

Read More »

Pre-Engineered Lifters accommodate angles up to 30 deg.

VectorForm(TM) Lifters double undercut capability in plastic molds. Lifter rod is actuated from sliding base, rather than static base in ejector plate. Mold designers can accelerate or decelerate movement of lifter core relative to ejector plate. Modular design of VectorForm Lifters allows ganging of multiple lifter systems to accommodate very large lifter cores. Guide Rod support system permits...

Read More »

Mold Bases are offered in 75+ trillion configurations.

SelectBase(TM) units are offered in 43 nominal mold base sizes (from 0808 to 2435) with 4 steel types and 9 plate thicknesses. Features include available clamp slot type (A, B, C, or D), location or omission of locating ring, and sprue bushing and sprue puller pin. Options include selection or omission of assembly screws, choice of stop pins and return pins, and either 3-piece or welded ejector...

Read More »

Mold Inserts include multi-purpose post.

Master Unit Die (MUD) Enhanced Series Mold Inserts have guide ejection system design, maximizing available insert core and cavity surface area. Guidepost retains and guides ejection system, and provides support without additional support pillars. Inserts are available in popular 08/09 insert thicknesses. They come with 4 leader pins, bushings, and return pins. Parting line plates are...

Read More »

Mold Dating Insert snaps in place.

Indexable mold dating insert allows molders to make fast changes to day, month, year or work shift without completely removing insert from mold. Date changes can be made with turn of screwdriver, while snap-in-place indexable adjustment ensures insert remains fixed in correct date position during production. Mold dating inserts are available in diameters of 6, 8, 10, 12, 16 and 20mm. Inserts are...

Read More »DME Brings Mold Technologies Expertise Closer to Molders and Moldmakers in Mexico

QuerÃ-©taro facility to provide mold components, hot runners and direct support to customers Madison Heights, Mich.Ã- – Molders and moldmakers in Mexico’s fast-growing plastics industry will have greater access to the advanced mold technologies expertise and support of global mold technologies supplier DME, as the company has established a permanent presence within Milacron’s...

Read More »DME Takes No. 2 Spot in National Quality Survey

Quality Leadership 100 Ranking Demonstrates Value Driven by Employee Commitment Madison Heights, Mich. –– DME Company, a leading provider of mold technologies to the plastics processing industry, has earned the No. 2 ranking in the 2013 Quality Leadership 100 Survey. DME jumped 28 spots on the list this year, coming in just behind Ford. Quality Magazine evaluated over 400 companies on a...

Read More »DME Accepting Scholarship Applications for Spring 2013 Semester

Mold technologies leader encourages students to apply for $1,000 scholarships before Dec. 1 deadline Madison Heights, Mich. - Attention college and trade school students interested in plastics: DME Company is accepting applications for its DME Plastics UniversityÃ-® Scholarship Program. The leading manufacturer of mold technologies encourages students to visit the DME website for complete...

Read More »DME Celebrates 70th Anniversary by Giving Back, Looking Ahead

Company will recognize 70 years of customer support with events, specials & other initiatives Madison Heights, Mich. - 2012 marks the 70th anniversary year of DME, a leading manufacturer of mold technologies and a global icon in the plastics industry. DME will celebrate this milestone with various expressions of appreciation for customers and partners throughout the year. The company will also...

Read More »

DME to Display Wide Range of Engineered Hot Runner Solutions at NPE

Learn how DME can be your most complete partner in mold technologies at booth #2803 Madison Heights, Mich. - DME Company, a leading manufacturer of mold technologies, will be presenting a wide range of its hot runner products at NPE 2012, booth #2803. For over 30 years, DME has offered a full spectrum engineered solutions essential for hot runner applications - everything from unitized valve...

Read More »

Interlocks feature interchangeable inserts.

Providing accurate alignment of plastic mold halves, Series IN2(TM) INovative INterlocks utilize interchangeable inserts, eliminating need to replace entire side interlock set during maintenance. Graphitic steel inserts are held in place with interference-fit design that retains them when interlocks are installed on mold. There are no coatings, which could peel away under severe conditions.

Read More »

Hot Runner System suits micromolding applications.

Designed for mold bases with tight center-to-center distances, externally-heated Stellar(TM) Hot Runner System works well with commodity and engineering grade resins in high-cavitation applications. Nozzles feature front-loaded design for tips, heaters, and thermocouples. Modular nozzle bodies are interchangeable and can be attached to manifold by threaded or compression connections. Multi-nozzle...

Read More »

Two-Stage Ejectors offer cut-to-length adaptability.

Hardened-Steel, Two-Stage Ejectors offer Bottom Last and Top Last styles in 20, 26, and 32 mm diameters. They control sequence of movement of 2 sets of ejector plate assemblies inside mold's ejector box. Both first stage and second stage strokes can be set independently. Once ejector system is installed, fixed strokes cannot be tampered with or accidentally modified. Latching mechanism eases...

Read More »

Hot Runner Nozzles suit direct gating applications.

Available in 10 lengths from 42-130 mm, Gate-Mate Lite nozzles feature square coil heater and integrated thermocouple. Conductive beryllium copper tip provides precise heat needed for proper gate control. Offered in point-gate or thru-hole tip styles, products have bodiless design that leaves no witness marks on finished molded part. They provide solutions for multi-cavity molds, thin-walled...

Read More »

Multi-Parting Line Systems target plastics processors.

Multi-Parting Line (MPL) Systems double cavitation of standard single-face molds. They can be configured as turnkey systems with mold bases, hot runner systems, temperature controllers, and centering devices. Stack Mold Components enable system customization. Dual Mold Carrier enables MPL molding utilizing existing single-face molds. Tandem Molding employs 2 mold faces with staggered processes,...

Read More »